Application of enzyme preparations in flour improvement

Release time:

2011-10-30

Amylase is a general term for a class of enzymes that can break down starch glycosidic bonds, including α-amylase (including fungal α-amylase and bacterial α-amylase), β-amylase, maltose amylase and glucoamylase. Commonly used are α-amylase and maltose amylase.

Main Enzyme Preparations Used in Flour Improvement

1.1 Amylase

Amylase is a general term for a class of enzymes that can break down starch glycosidic bonds, including α-amylase (including fungal α-amylase and bacterial α-amylase), β-amylase, maltose amylase and glucoamylase. Commonly used are α-amylase and maltose amylase.

1.1.1 Fungal α-Amylase

Fungal α-amylase is derived from Aspergillus oryzae and was the first microbial enzyme used in bread making. Because the amylase content of traditionally used malt is unstable and contains proteases, it is not suitable for industrial production. In contrast, fungal α-amylase has more stable activity and does not contain protease activity, so it is more widely used in industry. Fungal α-amylase can hydrolyze the α-1,4 glycosidic bonds of amylose and amylopectin to produce maltodextrin and maltose. Its optimum pH is 4.0-5.0, and its optimum temperature is 50-60℃. Practical application results show that after fungal α-amylase is added to flour as a flour improver, it mainly plays the following roles: In the dough, most starch exists in a crystalline state, and amylase cannot break down starch in its natural state. However, during milling, some starch granules are broken down to form damaged starch. In the presence of fungal α-amylase, these damaged starch granules are hydrolyzed into maltose (amylase can endolytically cleave amylose into dextrin, and dextrin is further degraded into maltose by the action of endoamylase). Maltose is then hydrolyzed into glucose by the maltase secreted by the yeast itself, providing sufficient sugar source as nutrients for yeast fermentation. Adding fungal α-amylase to bread can make the bread softer, enhance the extensibility and gas-holding capacity of the dough, and maltose can be utilized by yeast to produce CO2, thus increasing the bread volume. The presence of dextrin makes the bread texture loose, and it also has a good effect on improving the bread crust color, resulting in a pleasant bread after baking. Experiments also show that fungal amylase (FAA) can reduce the floury properties of wheat flour and improve the tensile properties of the dough. It has a significant effect on steamed bread, improving the quality, flavor, elasticity and volume of steamed bread.

1.1.2 Glucoamylase

Glucoamylase, also known as glucose amylase, is an exoenzyme. When acting on starch or glycogen, this enzyme can hydrolyze glucose from both ends of the starch, starting from the non-reducing end of the sugar chain, breaking the α-1,4 glycosidic bonds one by one in glucose units, and causing the glucose to undergo a conformational change from α-type to β-type. It can also slowly hydrolyze α-1,6 glycosidic bonds, converting them into glucose. The product of this enzyme acting on amylose is almost entirely glucose, and the products after acting on amylopectin are glucose and oligosaccharides with α-1,6 glycosidic bonds. Glucoamylase is mainly produced by mold and Rhizopus. At normal use concentration dissolved in water, the optimum pH is 4.0-4.5, and the optimum temperature is 58-60℃. This enzyme has good acid resistance, and its activity remains stable without decreasing at 25℃ and pH 3.0. The glucose hydrolyzed by this enzyme can participate in the Maillard reaction, increasing the color and flavor of the bread, and can also be used in frozen dough to allow the yeast in the frozen dough to act quickly.

1.2 Glucose Oxidase

The systematic name of glucose oxidase is β-D-glucose oxidoreductase. The mechanism of action of glucose oxidase is that under aerobic conditions, glucose oxidase catalyzes the oxidation of glucose to δ-D-gluconolactone, while producing hydrogen peroxide. The generated hydrogen peroxide is decomposed into H2O and [O] under the action of catalase. Glucose oxidase has a high degree of specificity; it only acts on the β-hydroxy group on C1 of the glucose molecule. It also has a wide pH range, with enzyme activity stable within a pH of 3.5-7.0. The temperature range it can tolerate is also wide, with little effect of temperature changes on enzyme activity within the range of 30-60℃.Gluten protein is composed of gliadin and glutenin. Cysteine in gluten protein is the key to the spatial structure of gluten and dough formation. The interaction between protein molecules depends on the number and size of disulfide bonds (-S-S-). Disulfide bonds can be formed intramolecularly (glutenin) or intermolecularly (gliadin). Glucose oxidase can convert glucose to gluconic acid in the presence of oxygen, simultaneously producing hydrogen peroxide. Hydrogen peroxide is a strong oxidizing agent that can oxidize the sulfhydryl groups (-SH) in gluten molecules to disulfide bonds (-S-S-), thereby increasing the strength of gluten. Generally, there are many exposed -SH bonds in the dough, and these sulfhydryl groups are easily oxidized. It has been reported that under the action of glucose oxidase, the content of -SH bonds in the water-soluble part of flour and dough decreases significantly. Glucose oxidase can significantly improve the flour quality characteristics, extend the stability time, reduce the weakening degree, improve the evaluation value, improve the dough's tensile properties, increase the tensile resistance, improve the gelatinization characteristics of flour, increase the maximum viscosity, reduce the breakage value, and form a more stir-resistant, dry and non-sticky dough. Glucose oxidase can effectively improve the bite of noodles and improve the surface state of noodles. The use of xylanase sometimes makes the dough sticky, which is due to the release of bound water, so xylanase is often used together with glucose oxidase. This combination can replace emulsifiers used in some bread varieties.In some practical applications, adding thiol oxidase can increase the effect of glucose oxidase. Thiol oxidase can specifically oxidize free thiol groups in the dough, and glucose oxidase and thiol oxidase have a synergistic effect. Glucose oxidase has a good effect on promoting the maturation of flour made from some new wheat, and the addition amount is only 45mg/kg. Through a series of experimental studies, it has been shown that glucose oxidase has a significant effect on the production of flour and its various products, both in terms of improving dough handling properties and improving product quality. The synergistic effect between this enzyme and other enzyme preparations and additives has given users more choices. As a new type of enzyme preparation, glucose oxidase is mainly used in bread-making flour. It can improve the gluten strength in the dough, enhance elasticity, and have better resistance to mechanical impact. In bread baking, it gives the dough good oven spring characteristics. Therefore, glucose oxidase can be an option as a substitute for potassium bromate. When using this enzyme, care should be taken not to add too much, otherwise it may cause the flour gluten to be too strong, causing negative effects on product processing.

1.3 Hemicellulase

Hemicellulases are a genus of complex enzymes, often referred to as xylanases or pentosanases. The most commonly used hemicellulases are derived from Aspergillus and Trichoderma, and their development and application research has been ongoing for nearly 10 years. The application of xylanase in baking is quite extensive. It plays the most important role among hemicellulase enzyme preparations, and its dosage is much smaller than that of traditional hemicellulase preparations. Its optimum pH is 4-6, and the optimum temperature is 50-60℃. Flour contains non-starch polysaccharides and pentosans, the main components of which are arabinoxylan and arabinogalactan peptide, with arabinoxylan accounting for 60%-70% of pentosans. Generally, wheat contains about 2%-3% arabinoxylan, of which 0.5%-0.8% is water-soluble, but it can bind 30% of the added water. Water-soluble pentosans have strong water retention capacity, generally absorbing 10-20 times their weight in water. Therefore, its own degradation and modification have a great impact on its function. Increasing water-soluble arabinoxylan in flour can increase the water retention of the dough.Under the action of endoxylanase, arabinoxylan in the dough will be partially hydrolyzed, and water will gradually be released from the dough, resulting in softening of the dough and increased mechanical strength. The final result is that in baking, crumb formation is slowed down, baking expansion increases the bread volume, and the crumb is softer. The action of endoxylanase is also enhanced by arabinofuranosidase, which can cleave the arabinose side chains of hemicellulose molecules, making the substrate more easily degraded by endoxylanase. Finally, both the stability and mechanical properties of the dough are improved. Enzyme preparations containing hemicellulase can solve the problem of flour due to the addition of dietary fiber. The presence of insoluble pentosans and coarse bran particles will interfere with the gluten network structure. Hemicellulase can dissolve part of the non-starch polysaccharides, thereby improving bread quality.Numerous experiments have shown that adding xylanase to flour can increase the solubility of insoluble arabinoxylan, improve the mechanical strength of the dough, increase the volume of bread, and improve the color of bread. Usually, there are endogenous enzymes in flour that can dissolve 15%-20% of insoluble pentosans. However, the addition of exogenous enzymes can increase the dissolution rate to 40%-65%. In bread production, 1/3 of the water is absorbed by pentosans in the dough. Due to their high water-binding capacity, they will affect the rheological properties of the dough. Generally speaking, water-extractable pentosans have a positive effect on bread, while water-unextractable xylan is detrimental to bread quality. The action of xylanase in the dough significantly increases the water-extractable arabinose, thereby improving the dough handling properties and stability, increasing the finished product volume, and improving the quality of the finished product. Experimental studies have shown that the effect of xylanase on the flour quality and tensile properties of the dough is not very significant. The effect on the quality of steamed food is not as good as that of glucose oxidase on the improvement of flour quality. It can significantly improve the stability time and evaluation value of the dough and reduce the weakening degree of the dough; it can significantly improve the internal structure and appearance of steamed bread and noodles.

1.4 Lipase

The application of lipases in the baking industry has only begun in recent years. Lipases act on ester bonds in fats, catalyzing the hydrolysis of triglycerides into diglycerides, monoglycerides, or glycerol. The microorganisms that produce lipases mainly include Candida, Aspergillus niger, Rhizopus, Pseudomonas, Staphylococcus, etc. The optimal pH is 6.0-9.0, and the temperature is 30-40℃. They can be activated by calcium ions and low concentrations of choline salts. Among them, the lipases used in the flour industry are derived from microorganisms. Lipases can be added to special flours for bread, steamed buns, and noodles. Adding lipases to bread flour can improve dough conditioning, increase fermentation stability, increase bread volume, create a uniform internal structure, produce a soft texture, result in a whiter crumb, and improve bread shelf life; the monoglycerides formed by lipase hydrolysis of fats can combine with starch to form complexes, thereby delaying starch aging and improving bread shelf life. Therefore, lipases are usually used with a small amount of fat, otherwise, the fat content in the flour is too low to achieve this effect. Even without added fat, lipases still have a certain effect, such as improving the structure and color of the bread crumb; adding lipases to steamed bun flour will have a similar effect to bread flour, especially for the old dough fermentation commonly used in China, lipases can effectively prevent excessive fermentation to ensure product quality; adding lipases to noodle flour can reduce spots on the dough, improve chewiness, prevent noodles from sticking or breaking during boiling, and make the surface shiny. Adding an appropriate amount of lipase to flour can significantly increase the tensile resistance and extensibility of the flour, addressing the problem of reduced extensibility after adding strong gluten agents.

1.5 Proteases

Proteases are a general term for enzymes that catalyze the breakdown of peptide bonds in proteins. Proteases act on proteins, degrading them into small protein peptides, polypeptides, and free amino acids. There are many types of proteases, widely present in all living organisms. According to their source, they can be divided into plant proteases, animal proteases, and microbial proteases; according to their properties, they can be divided into acidic proteases, neutral proteases, and alkaline proteases. Proteases are also one of the earliest enzyme preparations used in the flour industry, mainly used in biscuit flour and bread flour. Neutral proteases are commonly used in flour, with an optimal pH of 5.5-7.5 and an optimal temperature of around 65℃. After gluten protein in the dough is treated with protease, its mechanical properties and baking quality can be improved. Proteases can hydrolyze gluten protein, breaking peptide bonds in protein molecules, weakening the gluten, and softening the dough. The effect is better when used in strong flour, reducing dough elasticity and increasing extensibility, thereby improving mechanical properties. Compared with chemical reducing agents such as sodium bisulfite used to weaken gluten, proteases have strong specificity, fully demonstrating the advantages of bioenzyme preparations as flour improvers. Intracellular proteases from bacterial sources are rarely used in bread because they have an adverse effect on the network structure of gluten, but they can replace sodium metabisulfite in biscuits, crisps, desserts, and pizza making, as sodium metabisulfite destroys vitamins and produces excessive gas. Extracellular proteases can improve the color and taste of bread crust. Specific extracellular proteases have been developed that only hydrolyze terminal amino acids, releasing leucine and phenylalanine, which are components of the aromatic flavor of bread.

2 Advantages of Adding Enzyme Preparations to Flour

2.1 Convenient Use and Reasonable Dosage Baking enzymes are mostly dry and free-flowing baking granules with an average diameter of about 150μm; after dilution and compounding, they are free-flowing and dust-free, ensuring the accuracy and uniform mixing of online addition, which is more meaningful for manufacturers without a pre-mixing system.

2.2 Excellent Reaction Catalytic Properties Enzyme preparations used in flour improvement are a type of protein, whose main function is to catalyze various chemical reactions during food processing. Compared with other chemical improvers, its reaction conditions are mild, not requiring high pressure, high temperature, strong acid, strong alkali, high-speed stirring, etc., and the requirements for production equipment are not high; enzymes also have high specificity, strictly selecting the substrate, with one enzyme only acting on one reactant, or a class of compounds, or a certain chemical bond, and producing a certain target product, ensuring high safety.

2.3 In Line with the Development Trend of the Food Industry With the continuous development and progress of society, environmental protection, green, healthy, and safe products have become fashionable consumer pursuits. China actively advocates the principle of "natural, nutritious, and multifunctional" in food additive production, consistent with the international trend of "returning to nature, natural, nutritious, low-calorie, and low-fat" and the above-mentioned consumer demands. Therefore, while chemically synthesized additives are increasingly rejected by consumers due to their potential hazards, enzyme preparations have emerged. These high-tech biological products, mainly derived from cereals (malt powder), plants (papain), yeast (invertase), and microbial culture, are natural, green, non-toxic, and harmless to the human body, meeting the food-grade enzyme specifications recommended by the Food and Agriculture Organization of the United Nations, the World Health Organization, the Joint Expert Committee on Food Additives (JECFA), and the Food Chemicals Codex (FCC).

2.4 Compared with Other Improvers, Enzyme Preparations Have a Better Price-Performance Ratio Baking enzymes have been used earlier in Europe and America, with extremely wide applications, forming a large-scale industry that can be cultured, propagated, extracted, purified, and standardized under industrial conditions, thus reducing the production cost of various enzymes. Practice has proved that to achieve the corresponding baking effect, the addition amount and cost of compound enzymes are far lower than those of commonly used emulsifiers and gluten. From the perspective of some enzyme preparations that have been widely used in China, adding only about 20-40 yuan per ton of flour can achieve relatively ideal results.

BLOGS

On the occasion of International Women's Day, I would like to extend my sincere festival greetings to all the female employees working diligently in various departments of the company!

Geno Bio conducted first-aid knowledge and skills training

Geno Bio conducted first-aid knowledge and skills training

Public participation, fire prevention

Public participation, fire prevention

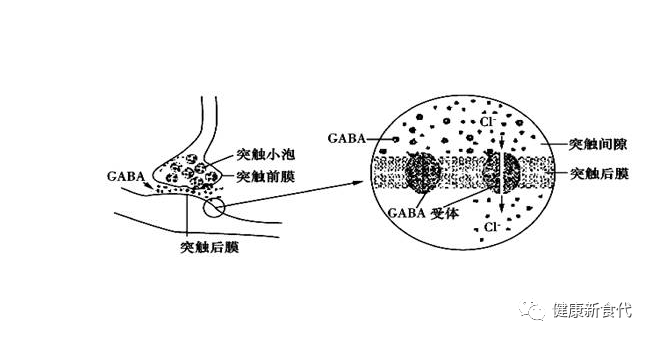

In-depth Interpretation - GABA (γ-Aminobutyric Acid)

In-depth Interpretation - GABA (γ-Aminobutyric Acid)

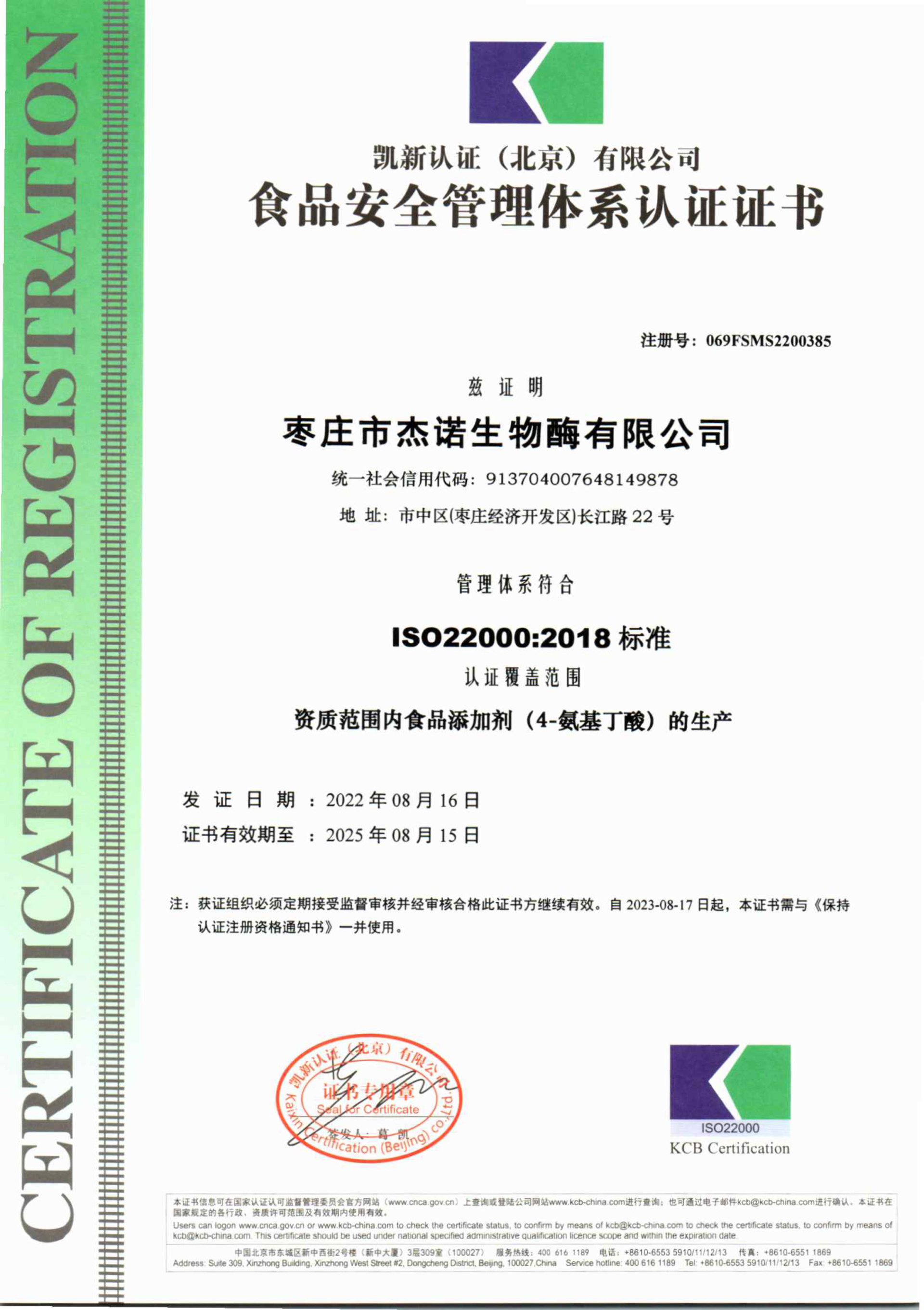

Zaozhuang Jeno Bioenzyme has passed the ISO22000 certification.

The company has obtained ISO22000 certification.