Application of enzyme preparations in vinegar production

Release time:

2013-05-17

In recent years, the reform of traditional vinegar production processes and the development and application of various new enzyme preparations have injected new vitality into traditional vinegar brewing. Practice has proved that the new process for vinegar production can not only reduce labor intensity and shorten the production cycle, but also reduce production costs, reduce environmental pollution, and improve product quality, making it worthy of promotion and application.

In recent years, the reform of traditional vinegar production processes and the development and application of various new enzyme preparations have injected new vitality into traditional vinegar brewing. Practice has proved that the new process for vinegar production not only reduces labor intensity and shortens the production cycle, but also reduces production costs, environmental pollution, and improves product quality, making it worthy of promotion and application.

Commonly used enzyme preparations in vinegar production

China's vinegar industry has mostly developed on the basis of ancient and backward production processes. With the continuous development of production, while maintaining its original characteristics, vinegar factories began to use pure yeast and solid saccharifying enzymes to produce fermented mash in large tanks at low temperatures, with saccharification and fermentation occurring simultaneously. Then, using acetic acid bacteria, using pools instead of tanks, solid-state layered acetic acid fermentation, the new process for vinegar production greatly improved labor productivity. In the 1990s, large domestic vinegar enterprises began to transform the original fermented mash process, which was a drop-type and open-type production method. They adopted a new process of crushing raw materials, adding high-temperature amylase, continuous cooking, saccharification with saccharifying enzyme, and then alcohol fermentation, achieving good results. Currently, the commonly used enzyme preparations in vinegar production include the following:

1. High-temperature resistant α-amylase (HTAA)

It is a liquid enzyme with a specification of 20000U/ml, added to the pulp preparation process before cooking. High-temperature amylase can hydrolyze the starch in the raw materials into soluble dextrin and a small amount of oligosaccharides at high temperatures, reducing the viscosity of the mash, which facilitates the flow and transportation of the mash. Its optimum operating temperature is 90℃-110℃, and the pH value is 6-6.5. Currently, a new type of acid-resistant and high-efficiency high-temperature amylase is being introduced to the market. Due to its good acid resistance, it is more suitable for situations where raw materials are prone to acidification during production. Without adjusting the pH value during saccharification, it is more conducive to the role of saccharifying enzyme, and the operation is simpler.

2. Medium-temperature α-amylase (LTAA)

Medium-temperature α-amylase is a liquid enzyme with specifications of 2000U/ml and 3000U/ml. Its mode of action is the same as that of high-temperature amylase. The optimum operating temperature is 7℃-90℃, and the pH value is 6-7. For production, either medium-temperature or high-temperature amylase can be selected according to different process conditions.

3. High-conversion saccharifying enzyme (GA)

Saccharifying enzyme is an exoenzyme, also known as glucoamylase. This enzyme is available in both solid and liquid forms, with specifications of 50000U/g and 100000U/g. It can hydrolyze α-1,4-glucosidic bonds from the non-reducing end of liquefied starch, producing glucose and a small amount of oligosaccharides. The operating temperature of saccharifying enzyme is 60℃, and the pH value is generally 4-5.

Application of enzyme preparations in vinegar production

Drawing on the "double-enzyme method" process of modern alcohol production is a major breakthrough in traditional vinegar brewing. Practice has proved that small and medium-sized vinegar factories can replace koji with saccharifying enzymes to improve raw material utilization, reduce production costs, and improve product quality.

1. Application of amylase

In vinegar production, after the raw materials are crushed and pulped, they must be cooked. The purpose is: (1) Under certain temperature and pressure, the cell tissues of starchy raw materials are completely broken, and the starch granules in the raw materials absorb water and expand, causing the starch granules to change from a crystalline state to a dissolved state of gelatinization; (2) The raw materials are thoroughly sterilized at high temperatures to prevent acid production during fermentation.

In order to dilute the thick mash when heated, to facilitate pipeline transportation, and to facilitate flow in the cooking pot, medium-temperature amylase needs to be added during pulping. When the temperature rises to 70℃, it reaches its operating temperature. As the temperature increases, the medium-temperature amylase takes effect, and the viscosity of the mash gradually decreases; when it reaches 90℃, the enzyme loses its activity, thus completing its role in the early stage of high-temperature cooking. When adding medium-temperature amylase, it is generally not necessary to adjust the pH value. The addition amount is generally 1U/g of raw material. Calculated at 2000U/ml, the added volume fraction is 0.05%. High-temperature cooking is a traditional process in China, with relatively mature technology. However, due to its high energy consumption, high equipment requirements, and the fact that high temperatures can cause excessive decomposition of starch, forming non-fermentable sugars and other substances, it is increasingly being challenged by new processes.

2. Application of saccharifying enzyme

The gelatinized mash after cooking is added with a certain amount of saccharifying agent (koji or enzyme) to further convert it into fermentable sugar. This process is called saccharification. Saccharification processes are divided into batch saccharification and continuous saccharification. Batch saccharification uses a single saccharification pot. After the mash is cooled to the saccharification temperature, saccharifying enzyme is added. At this time, it is generally not necessary to adjust the pH value; then, it is kept warm and stirred for 30-60 minutes before entering the fermentation process. The amount of enzyme added is generally 80-120U/g of raw material. Calculated at 100000U/ml, the added volume fraction is 0.1%; continuous saccharification is generally composed of several saccharification pots connected in series. The residence time of the mash in the pot is not less than 30 minutes. When saccharifying enzyme is added continuously, the addition rate must be controlled to be consistent with the mash flow rate.

In the selection of saccharifying enzyme varieties, for traditional solid-state fermentation processes using enzymes instead of koji, solid saccharifying enzymes can be selected; in batch saccharification, solid or liquid saccharifying enzymes can be directly added to the saccharification pot without dilution; in continuous saccharification, the saccharifying enzyme can be diluted with warm water before continuous addition; liquid saccharifying enzymes have higher concentration, higher activity, purer enzyme system, and fewer impurities, resulting in better effects than solid saccharifying enzymes; compound saccharifying enzymes further improve the yield of the final vinegar product, therefore, they have better effects than ordinary saccharifying enzymes.

3. Application of other enzyme preparations

In recent years, with the continuous emergence of more new enzyme preparations, various new processes are being continuously applied. Since the raw materials contain other components besides starch, such as cellulose and protein, using different types of enzyme preparations to convert them into useful substances that can be used in production will greatly improve the utilization rate of raw materials, help reduce costs, and reduce waste discharge.

(1) Adding cellulase to starchy raw materials. Adding cellulase to starchy raw materials can degrade cellulose into sugars that yeast can utilize, thereby increasing the alcohol yield. Its effective temperature is 50℃-70℃, and pH is 4-6.5. It is added during the saccharification process, with an addition amount of 0.04%-0.05%. During fermentation, the alcohol yield can be increased by more than 1%.

(2) Adding acid protease during the saccharification process. Although the raw materials contain a lot of protein, yeast cannot directly utilize it. Adding acid protease during the saccharification process can convert protein into polypeptides and amino acids, increasing the yeast-absorbable nitrogen in the mash, promoting yeast growth and reproduction, and improving the alcohol production rate. Due to the increase in α-amino acids, the amino acid synthesis metabolic burden of yeast cells is reduced, allowing more glucose to be directed to the fermentation of ethanol, thereby increasing the alcohol yield of the raw materials. The optimum pH value of general acid protease is 3-5, the effective temperature is 40℃-50℃, and the addition amount is 0.01%.

Vinegar brewing, as a representative of China's traditional brewing industry, must reform and innovate its outdated production processes to change its current production situation and continuously improve its production level and scale. In recent years, with the application of various new enzyme preparations, new vitality has been injected into this traditional industry, which will play a very important role in promoting its continuous development and progress.

BLOGS

On the occasion of International Women's Day, I would like to extend my sincere festival greetings to all the female employees working diligently in various departments of the company!

Geno Bio conducted first-aid knowledge and skills training

Geno Bio conducted first-aid knowledge and skills training

Public participation, fire prevention

Public participation, fire prevention

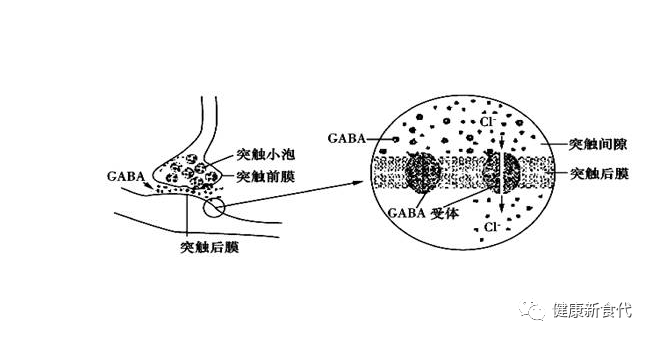

In-depth Interpretation - GABA (γ-Aminobutyric Acid)

In-depth Interpretation - GABA (γ-Aminobutyric Acid)

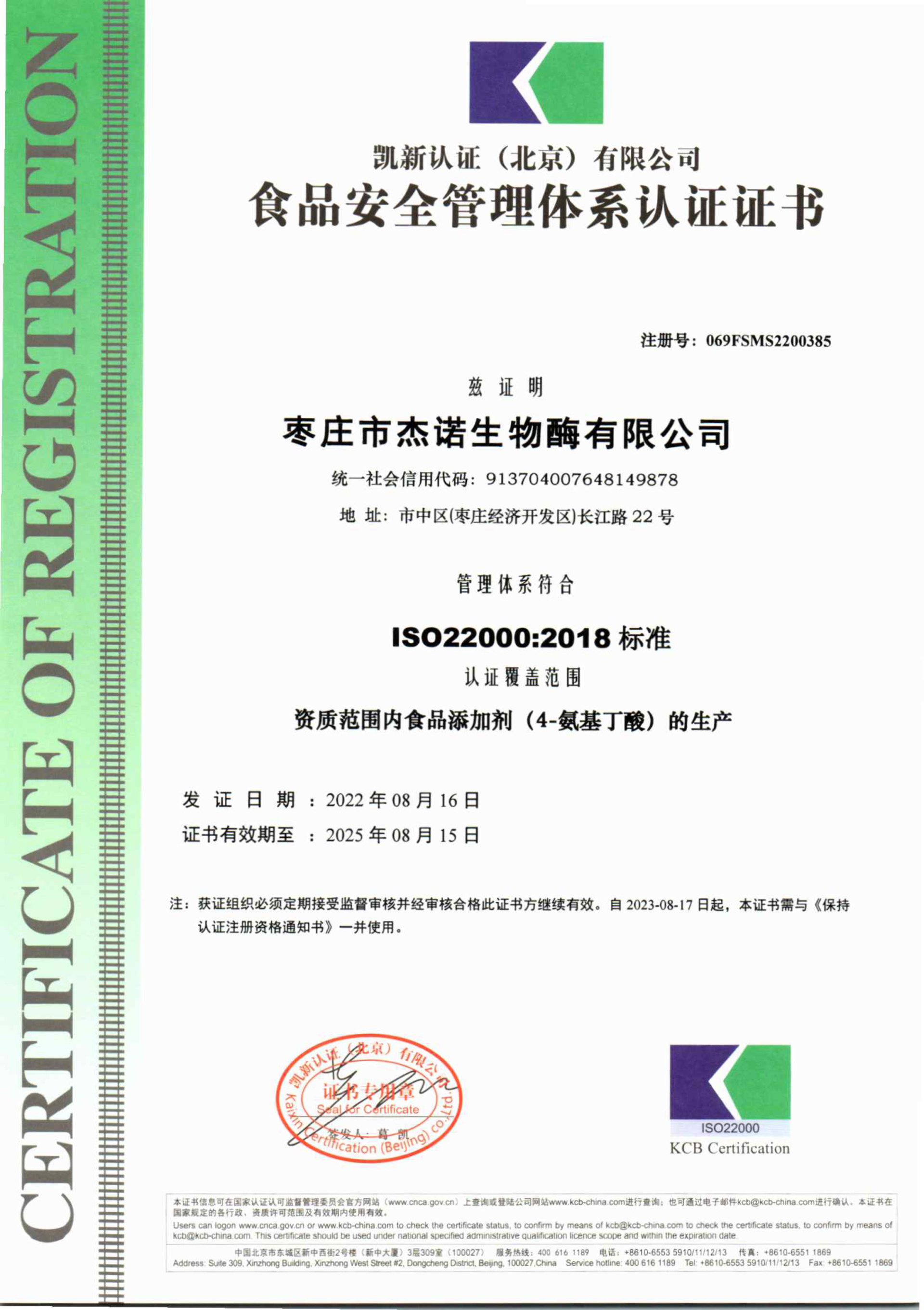

Zaozhuang Jeno Bioenzyme has passed the ISO22000 certification.

The company has obtained ISO22000 certification.