Products

Contact Us

Tel: 86-632-8999262

Fax: 86-632-8999268

MP/Wechat/Whatsapp: 8613563208832

E-mail: sdjienuoanna@hotmail.com

E-mail: annajienuoenzyme@hotmail.com

E-mail: sdjienuo@163.com

Add: No.22 Chang Jiang Road, Economic Development Zone, Zaozhuang City, Shandong Province, China

Alginate lyase

Alginate lyase is produced by our company through liquid deep fermentation and refined extraction from excellent strains introduced from abroad. It can effectively hydrolyze alginate under neutral pH 6-8 conditions and can be widely used in the processing of brown algae, sodium alginate, and alginate oligosaccharides.

Details

Alginate lyase is produced by our company through liquid deep fermentation and refined extraction from excellent strains introduced from abroad. It can effectively hydrolyze alginate under neutral pH 6-8 conditions and can be widely used in the processing of brown algae, sodium alginate, and alginate oligosaccharides.

I. Principle:

Alginate is a linear polysaccharide composed of α-L-guluronic acid and its isomer β-D-mannuronic acid linked by 1,4 glycosidic bonds. Alginate lyase degrades alginate through β-elimination catalysis, forming an unsaturated double bond between C4 and C5, and producing a degradation process at the reducing end, ultimately degrading the long-chain polysaccharide into short-chain oligosaccharides.

II. Product Specifications:

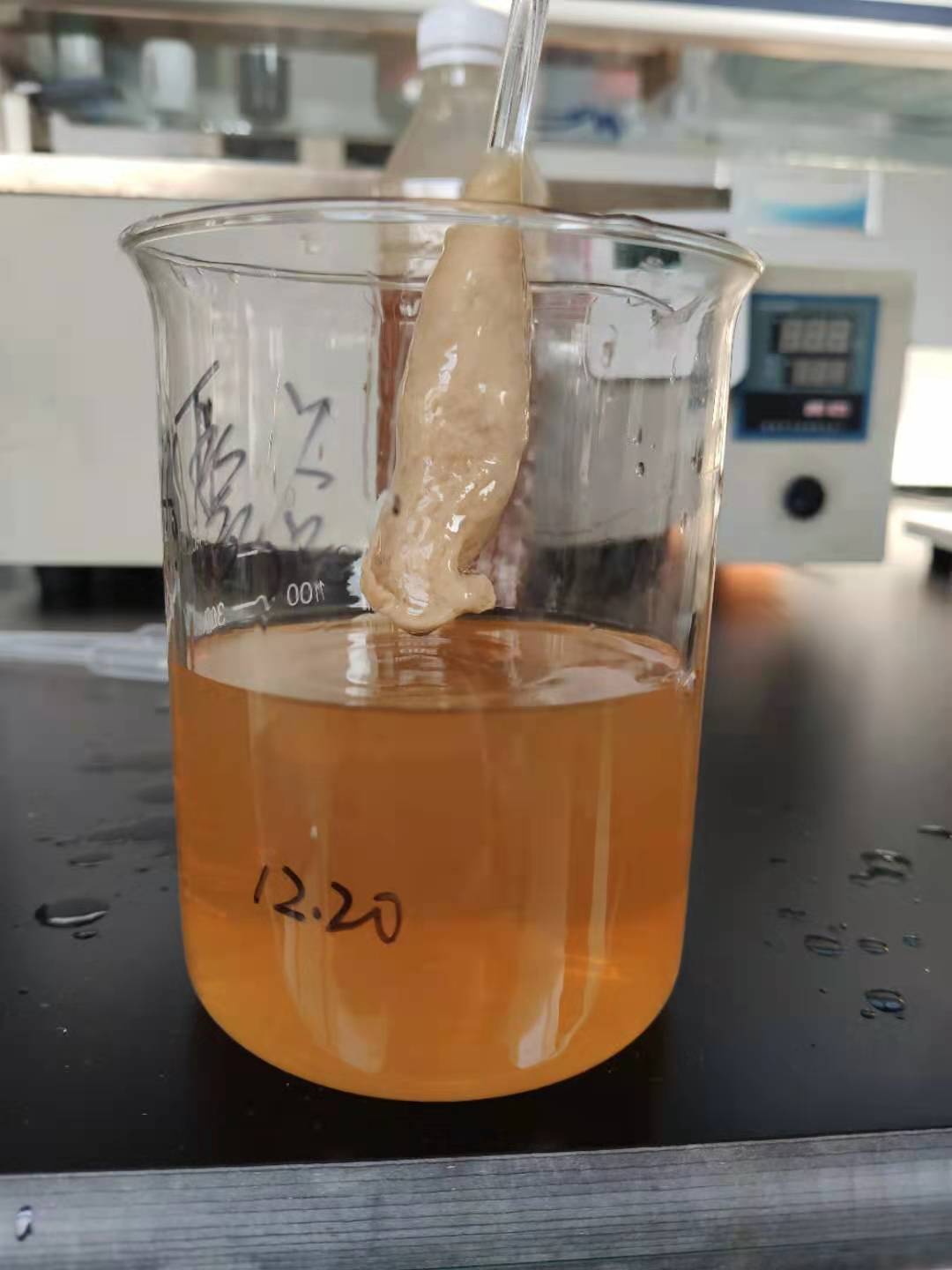

Liquid type: Brownish-yellow liquid 10000U/ml 25KG/barrel

Solid type: Yellow powder 250000U/ml 25KG/barrel

No less than the calibrated enzyme activity at room temperature for six months, avoid high temperature and sun exposure.

Enzyme activity definition: 1 ml of liquid enzyme degrades alginate to produce 1 μg of reducing sugar per minute at 40 degrees, which is 1 enzyme activity unit, expressed as U/ml;

III. Usage:

In the production of pure alginate degradation, taking solid enzyme as an example (the amount of liquid enzyme added is generally 5~7.5%; the amount of solid enzyme added is generally 0.2~0.3%), 2% sodium alginate aqueous solution (sodium alginate: Solarbio, reagent grade), initial viscosity of about 700, under the condition of stirring at 35 degrees, add 0.3% of solid enzyme (based on sodium alginate), after 5 minutes, the viscosity drops to 10, after 1 hour, the hydrolysis is completed, the alginate solution becomes a watery liquid, the product molecular weight is 200~2000, and the degree of polymerization is 2~10.

IV. Difference between enzymatic method and traditional method:

| Traditional process | Enzyme process |

Reaction conditions | pH =11, 70℃, | pH=6~8, 45℃ |

Different products | Oligosaccharide molecular weight: 200~400, low degree of polymerization | Oligosaccharide molecular weight: 200~2000, uniform distribution |

Operation process | A large number of chemicals, complex process | Simple process, high product purity |

Our company will work with you to improve the process and solve problems. Please let us know your needs, and we will do our best to serve you.

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!