Products

Contact Us

Tel: 86-632-8999262

Fax: 86-632-8999268

MP/Wechat/Whatsapp: 8613563208832

E-mail: sdjienuoanna@hotmail.com

E-mail: annajienuoenzyme@hotmail.com

E-mail: sdjienuo@163.com

Add: No.22 Chang Jiang Road, Economic Development Zone, Zaozhuang City, Shandong Province, China

Highly efficient kelp hydrolase

This enzyme is a highly efficient hydrolase specifically developed for kelp (brown algae), produced by our company through liquid deep fermentation and purification using superior strains imported from abroad. It can be used on both dried and fresh kelp (whole kelp) and is widely applicable in the seaweed fertilizer processing industry.

Details

High-efficiency kelp hydrolase

This enzyme is a specialized, high-efficiency hydrolase for kelp (brown algae), developed using superior strains imported from abroad and refined through submerged fermentation. It can be used on both dry and fresh kelp (whole kelp) and is widely applicable in the seaweed fertilizer processing industry.

I. Advantages of enzymatic kelp hydrolysis:

1 Significant cost advantage in production: The hydrolysis process does not require high-temperature heating, saving energy and reducing emissions, and can save more than 20% of the total cost.

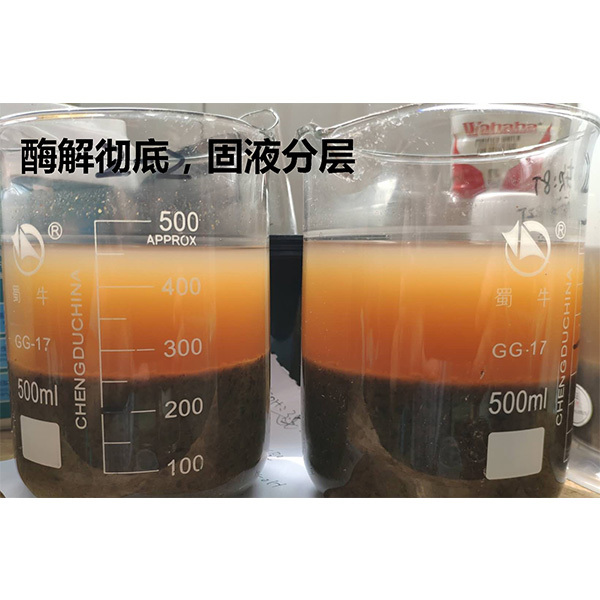

2 High-quality hydrolysate: Kelp is not subjected to strong acid-base reactions, but directly undergoes enzymatic catalysis, maximizing the retention of natural active substances in seaweed, and the hydrolysis rate can reach 90%.

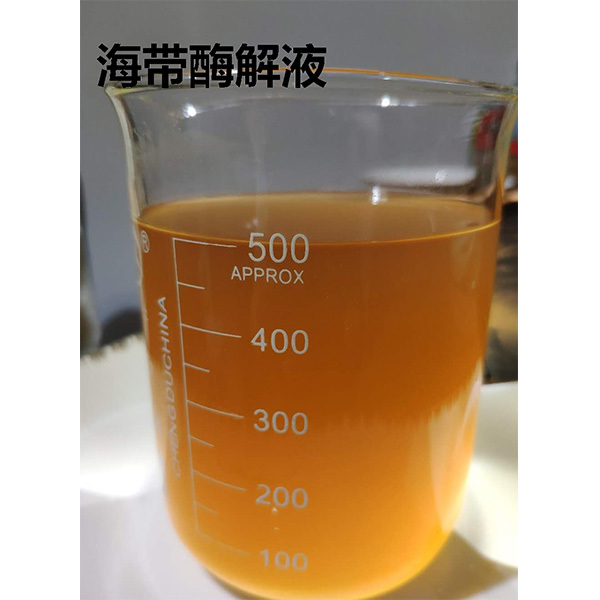

3 The finished hydrolysate is a transparent light brown color, with good sensory appeal.

II. Usage:

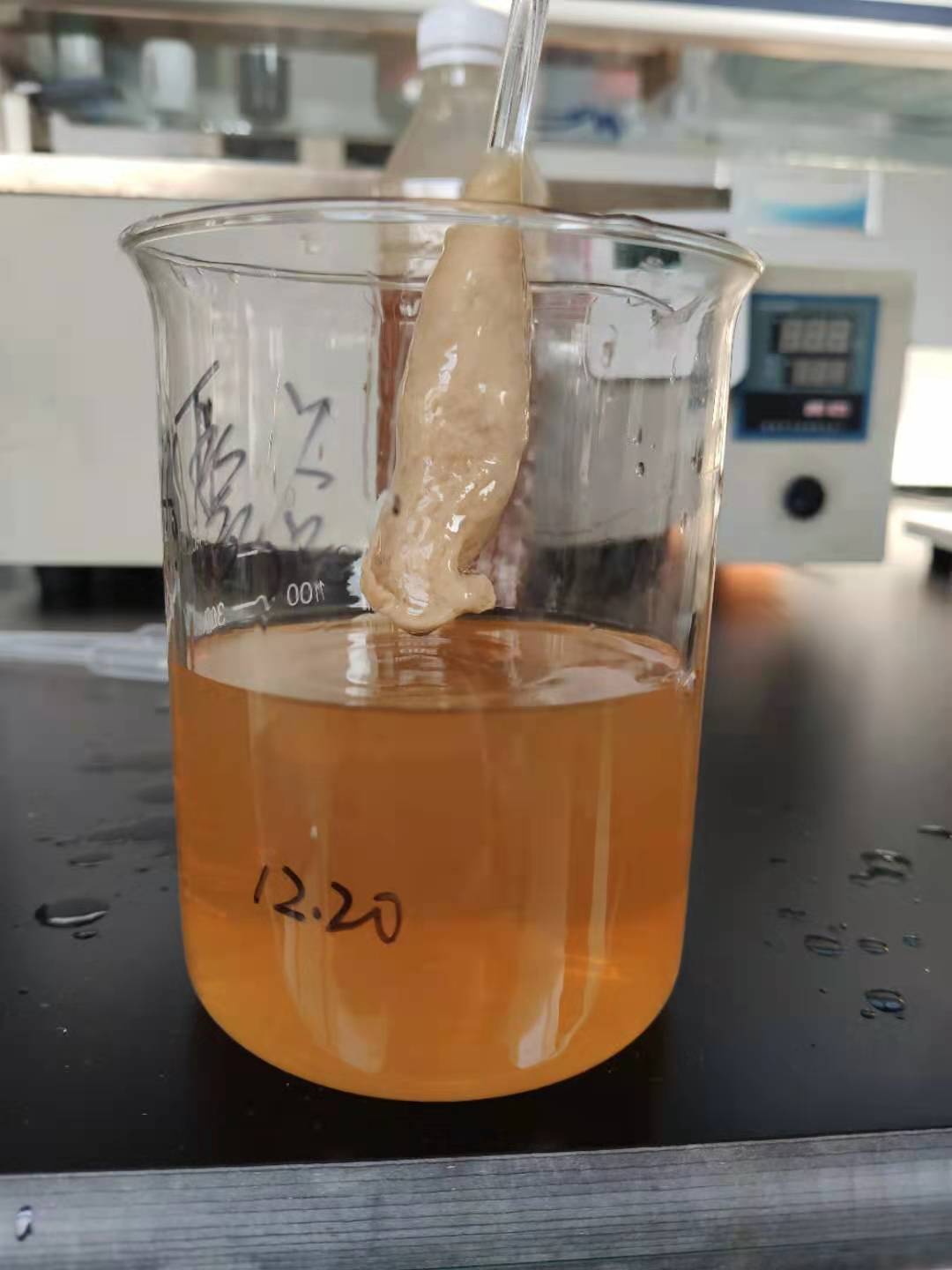

1 Pre-treatment: Based on the weight of dry kelp/dry kelp powder, add 8-15 times the amount of water to the processing container (adjust according to kelp quality). For fresh kelp, add a small amount of water directly to make a pulp. After heating to 40-45 degrees, add 8% of the dry kelp weight of a special softener, mix well, and then add the material for softening. Depending on the dryness of the kelp and the harvesting season, the softening time is 3-8 hours (intermittent stirring, thorough mixing).

2 Enzymatic hydrolysis: After the raw materials are fully softened, add 2% of the hydrolase based on the weight of dry kelp and stir for enzymatic hydrolysis for 6-12 hours.

3 After enzymatic hydrolysis: Normal centrifugation.

III. Conditions and precautions for enzymatic hydrolysis reaction:

- Reaction temperature: 42-45℃

pH Value: around pH 6-8. If the pH of the system drops to 6 during this period, 10%-20% potassium hydroxide can be used to adjust it to pH 7.0-7.5.

- During the enzymatic hydrolysis reaction, slow stirring should be used to ensure uniform temperature inside the reaction vessel. When adding potassium hydroxide to adjust the pH, avoid excessively high local concentrations, which can cause enzyme inactivation.

- Sargassum and green algae should use other related hydrolase products from our company.

IV. Product specifications: Solid powder 2Kg/sealed bag, 20kg/barrel.

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!