Products

Contact Us

Tel: 86-632-8999262

Fax: 86-632-8999268

MP/Wechat/Whatsapp: 8613563208832

E-mail: sdjienuoanna@hotmail.com

E-mail: annajienuoenzyme@hotmail.com

E-mail: sdjienuo@163.com

Add: No.22 Chang Jiang Road, Economic Development Zone, Zaozhuang City, Shandong Province, China

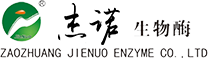

Alkaline Protease

The Alkaline Protease is a solid enzyme produced by submerged fermentation from Bacillus Llicheniformis. Its main ingredient is Bacillus Licheniformis Protease which is endo-protease of serine type. It can hydrolyze peptide chain of protein molecule into polypeptide or amino acid with strong protein decomposition capacity. It is widely applied in production of food, heparin sodium, chondroitin, silk degumming, leather depilation and softening, detergent and etc.

Keywords:

Details

Brief Introduction:

The Alkaline Protease is a solid enzyme produced by submerged fermentation from Bacillus Llicheniformis. Its main ingredient is Bacillus Licheniformis Protease which is endo-protease of serine type. It can hydrolyze peptide chain of protein molecule into polypeptide or amino acid with strong protein decomposition capacity. It is widely applied in production of food, heparin sodium, chondroitin, silk degumming, leather depilation and softening, detergent and etc.

Definition of Activity:

One gram of solid Alkaline Protease powder at 40°C and pH 10.5 hydrolyze casein in one minute to produce 1μg tyrosine is defined as one enzyme activity unit and marked with u/g.

Characteristics:

1. Alkaline Protease can efficiently hydrolyze the protein into free amino acids.

2. Effective temperature: 20-65°C Effective pH: 8-12

Optimum temperature: 40-50°C Optimum pH: 9-11

Specifications:

|

Attribute Name |

Attribute Value |

|

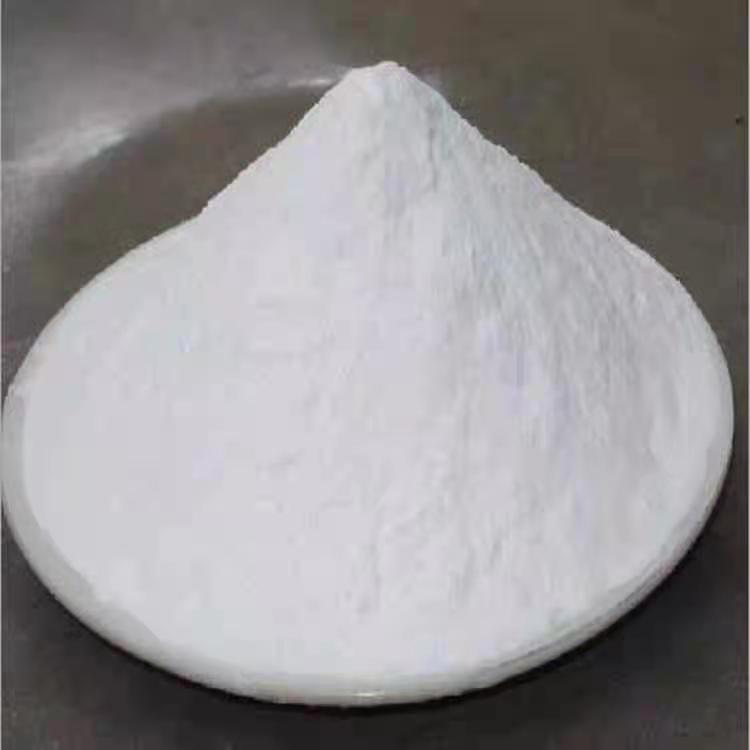

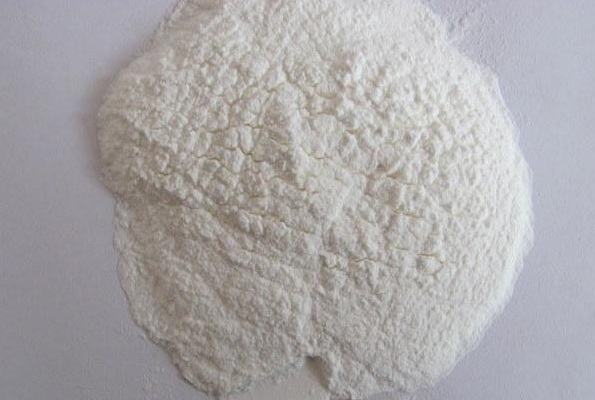

Appearance |

Yellow-Brown Powder(no deliquescence and caking) |

|

Enzyme Activity |

100,000 u/g, 200,000 u/g, 300,000 u/g, 400,000 u/g |

|

Water Content |

≤ 8% |

|

Particle Size |

≥90% pass 40 mesh |

Application & Reference Dosage:

1. Application in Heparin Sodium Industry:

a. Add salt and alkali at earlier stage. The process is the same with salt dissolving.

b. Rise the low temperature to 65°C and keep 1 hour.

c. Cool down the temperature to 45°C and add 3g enzyme powder (100,000 u/g) for one piece of small intestine.

d. Rise the temperature to 60°C after adding the enzyme and keep 4-6 hours.

e. Filtering after rising the temperature to 80°C.

f. Add Resin when the temperature is cooled down to 60°C after the filtering.

g. The procedure of dissolving salt is different.

Adjust the dosage and the enzymolysis condition according to the quality of raw materials and the practical production conditions.

2. Application in Chondroitin Industry:

a. Stir the enzyme well with water, and then add it into the materials.

b. Add 0.4%-0.6% of enzyme powder during the whole process of enzymolysis dissolution. Add the enzyme separately by twice. Add 60-70% of the total enzyme in the front two thirds time and add the rest enzyme during the left time.

c. Enzymolysis condition: Adjust the temperature to 45-60°C and pH at 10.5. Process time: 5-8 hours. Stir once every 30mins.

Adjust the dosage and the enzymolysis condition according to the quality of raw materials and practical production condition.

3. Pretreatment in Silk Degumming Industry:

Pretreatment → Dehydration → acid treatment (add protease 18-24 u/ml and soap 0.75% at 48-50°C and pH 10.5) → Dehydration → skin tearing off → washing →Dehydration → fluffing → drying → fluffing

4. Application in Leather Depilation Industry:

Raw Hides → washing → degreasing → alkali expansion → feather plucking → splitting → dealkalization → enzyme depilation → washing → pickling →tanning.

Advantages:

a. Simplify production process and reduce production period.

b. Improve end product quality, leather yield and reduce production cost.

c. No pollution to the equipment, environment and leather.

d. Environmental-friendly & bio-degradation.

5. Food Industry:

Alkaline Protease can be applied in animal and plant protein hydrolysis of food industry, produce polypeptide or amino acid, form special favor of protein hydrolysis liquid which can be widely used in seasoning liquid and health care industry.

6. Application in Detergent Industry:

a. Alkaline Protease can decompose protein based stains like grass, blood, mucous, milk, meat, faecal material, human sweat and etc. into small, readily soluble peptides and amino acids which can be easily removed during washing process and thus improving the cleaning efficiency of detergents.

b. Alkaline Protease added in the toothpaste, toothpowder, Mouth Refreshner helps the tartar removing.

c. It can also be used to clean biochemistry instrument as medical reagent with unique washing performance.

Storage:

Should be stored in a cool, dry and well-ventilated place; protect from direct sunlight, heat and dampness; avoid storing with poisonous and harmful substances.

Shelf Life: Enzyme activity remains ≥ 90% after 12 months at room temperature 25°C.

Packaging: 20kg/bag or as clients’ requirements.

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!